=space

This post is mainly about a design concept for far-future large space habitats.

some proposed designs

As

you can see on

Wikipedia, many

space habitat designs have been proposed. Below are some that I thought were

worth mentioning.

current space stations

Obviously, space stations with long-term occupants have already been made,

the biggest being the

ISS.

issue: small modules

Each launch lifts a complete

cylindrical module, and then the modules are assembled. This limits module

diameter, which has some problems:

- To be able

to move things through the center of modules, much of the volume must be

left empty.

- The large surface area relative to volume makes

radiation shielding and thermal insulation less efficient.

- Wires

and pipes between modules must go through several connections.

ISS maintenance

The ISS has some purposes:

1) National

prestige.

2) Studying the effects of long-term spaceflight on humans.

3) Inspiring kids by having humans in space.

4) International

cooperation.

The thing is, (4) is no longer

very relevant, and a new space station wouldn't accomplish the other things

much better than the existing one. And that's why the ISS is still in orbit

past its planned lifetime.

The ISS costs ~$3 billion/year to operate,

and it has major maintenance

problems. At this point,

it might be cheaper to build a new station and abandon the ISS than it is to

continue using it, considering that SpaceX is making Starship anyways. NASA

seems to

agree.

Maybe some equipment from the ISS could be brought down and sold to

collectors/museums? Some people would probably pay a lot.

Then, if

you're making a new station, people might want to see something visibly

different. "You want to spend billions of dollars to do the same thing

again? We were supposed to learn stuff and make progress from the first

time."

inflatable modules

One way

to launch modules bigger than the launcher is to make inflatable modules.

Multiple companies are working on this, including Axiom Space and Lockheed

Martin. This was even tested in

space.

Here's a video of Bigelow

modules.

issue: polymer degradation

Exposed

polymers in space degrade fairly quickly. The reason that flexible

inflatable modules are maybe practical is, they'd be covered with vacuum

insulation using

layers of aluminum. Radiation damage would still be a long-term problem, but

inflatable modules might last long enough for a space station project.

Spacesuits have used fabric based on glass fiber and

teflon largely because it resists

damage from the atomic oxygen in space.

issue: bending fabric

The walls of inflatable modules must be thick enough to contain pressure

and have insulation. That means the bending radius has to be somewhat large.

There's also the possibility of damage where the walls are bent, and the

Bigelow module test had some problems inflating because the fabric stuck to

itself.

geodesic spheres

Another

obvious way to get a space station with more internal volume is to launch a

stack of panels that are welded together into a sphere. The panel pattern

would be a geodesic

polyhedron.

A

company called ThinkOrbital has been working on

such a design; see this paper.

The design in that paper would have 2x the volume of the ISS, from a single

launch. It was later redesigned to use a SpaceX Starship launch and have 2x

that volume.

ThinkOrbital's approach involves metal panels welded

together using a robotic arm with an electron beam welder. The basic concept

seems entirely feasible to me. Many people guess that doing welding in space

is a big problem, but it was done by the Soviet Union. I personally like

this concept better than inflatable modules.

comments on

ThinkOrbital

ThinkOrbital proposed using aluminum alloys,

but aluminum welds are weak. So, they proposed panels that are thicker at

welds, but another solution is to use steel or titanium instead, at least at

the panel edges. Titanium should also warp less from welding than aluminum.

To me, titanium seems like a better option for panels here than aluminum.

ThinkOrbital specifies panels as big as the launcher can hold, to

minimize welding. With titanium panels, maybe the panels should be smaller

to make the handling equipment lighter and reduce tooling costs.

issue: insulation gaps

If the insulation is

integrated into the panels, then there will be gaps in the insulation where

panels meet. Obviously there are ways to deal with this, but that adds a

little complexity.

issue: no gravity

Of

course, current space stations have no gravity. This is useful in some ways,

but also causes a lot of problems: health problems, particles floating

around, lack of convection, etc.

rotating wheels

So, you want gravity, which means rotation, and you probably want to be able

to roll stuff around the station. The obvious solution to that is a rotating

ring, which was proposed back in 1903 by Tsiolkovsky. Here's

Wikipedia on

that, and here's an old example

design.

issue: radiation

shielding

Having a lot of surface area relative to volume

makes radiation shielding harder. How much of a problem is radiation in

space?

This

paper notes:

Forty-eight cases of severe lens opacification (16.2%) were observed among the 295 NASA astronauts who participated in the LSAH (Longitudinal Study of Astronaut Health) study, but 86% of the astronauts who stayed in space suffered from a pathology of the eye.

The bone loss seen in

astronauts has generally been attributed just to lack of gravity, but I

think radiation is responsible for a significant fraction of it.

That's from being in low earth orbit, and even in LEO the Earth's magnetic

field provides significant protection. In interstellar space, at the same

distance from the sun, radiation doses are ~1000x

higher.

Radiation shielding must then be at least 10mm thick even for short-term

usage.

issue: large-scale industry

Nobody's

building large space habitats anytime soon, but here we're considering

what would be necessary for a self-sustaining space-based civilization, and

the economy for that would probably require a large scale. Industry often

has large minimum scales for manufacturing things efficiently. If production

is distributed across many small wheels, transporting items between them is

difficult.

big rings

If radiation

shielding and industry minimum scales are a problem, let's try going bigger.

What if we increase the ring diameter?

The ultimate example of that

would be a Ringworld: a ring all

the way around a sun. That's been seen in some SF but it's rather

impractical.

issue: orbit stability

The orbit

of a ring around a sun isn't stable. Any perturbation will increase over

time until the ring breaks apart.

So, let's consider a much smaller

ring that orbits around a sun, instead of going all the way around a sun,

but is still large enough for a complete economy.

issue:

material strength

The Ringworld book has the ring rotating

faster than its orbital speed to provide gravity. The thing is, for a given

amount of centrifugal force, required material strength is proportional to

radius. You really want a diameter less than a few kilometers for 1g of

gravity.

issue: lack of modularity

How do you

gradually construct a very large ring while using it? That seems difficult.

issue: material transport

Transporting materials

inside a large space station with no gravity is easy. With no weight to

support, payloads can simply float towards their destination.

With a

large-diameter ring, materials must be moved inward a long distance to make

them weightless. Axial transport is then easy, but there's only a short

axial distance to travel. Obviously, it's possible to transport materials on

wheeled vehicles, but we'd prefer not to need to.

long cylinders

OK,

large-diameter rings require strong materials and are hard to make. So,

let's try increasing length instead.

Arthur C. Clarke wrote

about a large rotating

cylindrical space habitat back in 1973.

issue: rotation

stability

When a narrow object is spun along its long axis,

its rotation is not stable. If there's some energy dissipation from flexing

or sloshing, its rotation eventually changes to its axis of greatest

rotational inertia; that's the Dzhanibekov

effect.

So, a cylinder would end up spinning the wrong way.

O'Neill proposed

a pair of counter-rotating

cylinders. That mitigates

the rotation stability issue, but then...

issue: rigidity

Consider holding a piece of cooked spaghetti from one end and spinning

it along its long axis; the spaghetti won't stay straight. Very long and

thin cylinders could have a similar problem.

issue: bearings

If a pair of counter-rotating cylinders is used, they need to be

connected by bearings.

It's not practical to perfectly balance those

cylinders, so they'll tend to wobble slightly. So, bearings between them

must be flexible enough to handle some relative movement. If the wobbling

tendencies of rotating cylinders are cancelled out with counter-rotation,

then the bearings must exert enough force to do that, and they'd probably

need active control. The longer the cylinders, the more torque must be

exerted on them to keep them balanced.

big rotating spheres

If a

big ring is too wide and a rotating cylinder isn't stable, we could

compromise and use a big rotating sphere. That's a "Bernal

sphere". Obviously, that can't

be as big as a very long cylinder, but let's suppose industry could be

streamlined to the point where a whole economy could fit in one of those.

(If you can accept 0.5g gravity, then the diameter could be doubled.)

If you're looking for a much bigger sphere for a SF story, maybe what

you want is a bubbleworld.

issue: no microgravity zone

There's no large

volume where materials can be floated around freely. Having that is useful

for industry and transportation.

issue: no doors

Most proposed large cylindrical space habitats have large open areas. If

something causes a large air leak in one section, it would then be

impossible to contain the leak. Of course, doors could be added, but they'd

need to contain the air pressure. So, section doors would need to be large

hemispheres, which would take up a lot of space. That's at least possible

for cylinders, but with a sphere, there's really no way to add internal

bulkheads.

issue: lack of modularity

A long

cylinder can be gradually extended, but expanding a sphere gradually is much

harder.

bhabitats

Above, we ruled

out small disconnected habitats, large-diameter rotating rings, and very

long rotating cylinders. So, to get some gravity, the only remaining option

is many small rotating structures connected together in a way that allows

for easy material transport.

Here's a space habitat design I made on

that basis. For now, I'm calling this type "bhabitats". The basic concept

is: many pressurized spheres that each connect to other spheres and to

rotating cylinders, in a modular way.

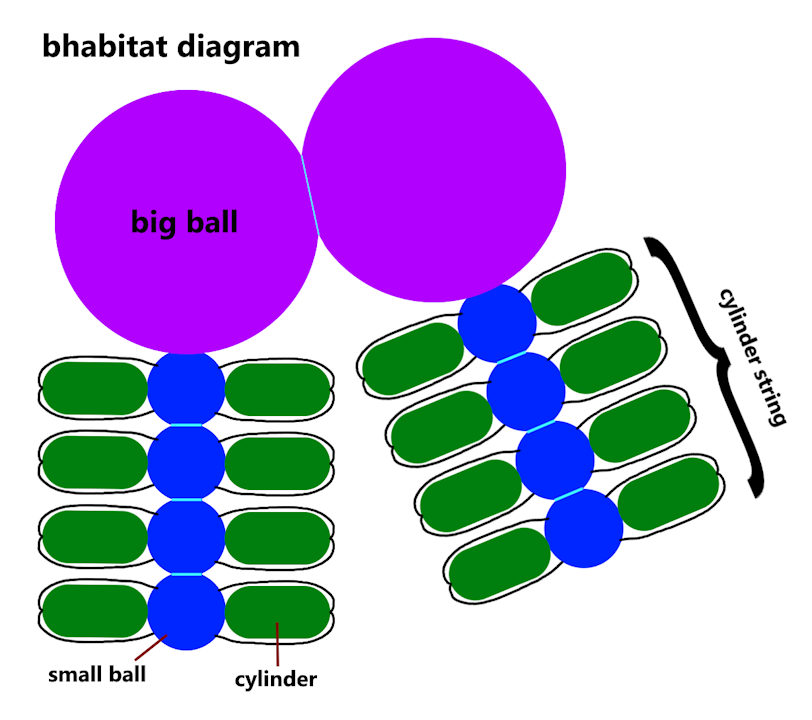

diagram

Here's a diagram of

a large assembled bhabitat.

expansion steps

first small ball

Make a sphere of maybe 600m diameter, maybe

out of iron. It might be made by welding polygonal panels together.

The sphere should have 8 locations where ports can be added: 6 small ports

and 2 medium ports. Small ports allow for relative rotation.

Fill the

sphere with air. Now, there's a pressurized environment with a little bit of

radiation shielding.

make some shielding

There are 2 things you want for radiation shielding: a magnetic field, and

lots of mass. Here, a magnetic field means superconducting coils. Ideally,

most of the shielding mass would be easily-available material, such as rocks

collected in space.

Make a big superconducting coil that goes around

the habitat. Also make some movable panels containing rocks, and place them

around the habitat.

Now, there's a pressurized environment with

better radiation shielding.

first cylinder

Make a cylinder of maybe 400m diameter with hemispherical ends, maybe 800m

long in total. Connect one cylinder end to a small port of the small ball.

Spin the cylinder and small ball in opposite directions.

Now, there's

some living space with gravity.

2 cylinders

Connect a 2nd cylinder to the small ball on the opposite side of the 1st,

and rotating in the opposite direction.

Now, there's no need for the

small ball to rotate. So, shielding panels can be attached to the small

ball.

3 cylinders

Connect a 3rd cylinder, for

3 in total. Now, the habitat can freely change its orientation by adjusting

rotation rates of cylinders.

first cylinder star

Connect 3 more cylinders to the small ball, for 6 in total.

first cylinder string

Connect the small balls of

multiple cylinder stars, using their medium ports.

first big

ball

At the end of the cylinder string, make a sphere of

maybe 2km diameter. It should have 1 medium port to the cylinder string, and

locations for 2 large ports for connections to other big balls.

Now,

the habitat has a large microgravity area for industry, which also provides

shielding from that direction.

main string

Connect big balls together using the large ports. Optionally, connect the

cylinder strings with a truss for structural strength.

To make space

for the cylinder strings, the big balls need to be rotated somewhat unless

they're very large. The above diagram shows a partial ring of cylinder

strings; another option is cylinder strings on alternating sides, but that

would've made for a bigger diagram.

Yes, it's possible to make a 2d

grid of big balls, but that wouldn't give enough area for solar panels and

radiators.

component design

cylinders

The above sections described 400M diameter

cylinders. Such cylinders might have 20 floors, ranging from 1g to 0.5g,

with a hollow section in the center.

At 400M diameter, the material

requirements for 1g are very reasonable and the structure can be

lightweight. One reason for larger diameters being proposed is concerns

about motion sickness, but I think that, like with boats and VR movement,

people would get used to it. Certainly, you could go bigger without making

structural mass a big problem, but a smaller diameter has some advantages

for internal transportation. Shorter elevators to the center are better, and

very thick cylinders could have elevator capacity problems, much like

skyscrapers do today. Another issue with very large cylinders is, they'd

need larger linear actuators at the port for a given amount of wobbling.

To maintain mass balance, the cylinders need some movable masses. The

balancing system might use:

- 2 rings of

rails around the cylinder, 1 near each end.

- A set of heavy vehicles

that travel around the rail rings to balance the cylinder.

small ports

The bearings can use an ionic liquid layer or gallium alloy to contain

the air.

Some cylinder wobbling is inevitable. You need:

- flexible

connections to the bearing, probably corrugated tubes

- active damping

with linear actuators

electrical connections

Electric power can be transferred through liquid metal sliding contacts,

maybe using both NaK eutectic and gallium alloy. Those are used

today for

applications including wind turbines and rotating radars.

We can send

electricity through an arm to the far side of the cylinder, and have the

rotating electric contacts near the center.

internal

transportation

Most transportation would start with an

elevator towards the center of a cylinder. At the center, cargo could be

moved with propellers and small wings, like airships without the gas

bladders. Near the center, thrower/catcher devices that can handle 15 mph

could launch payloads anywhere along the cylinder, without occupying the

center path used for traffic to/from the port.