=chemistry =energy =economics

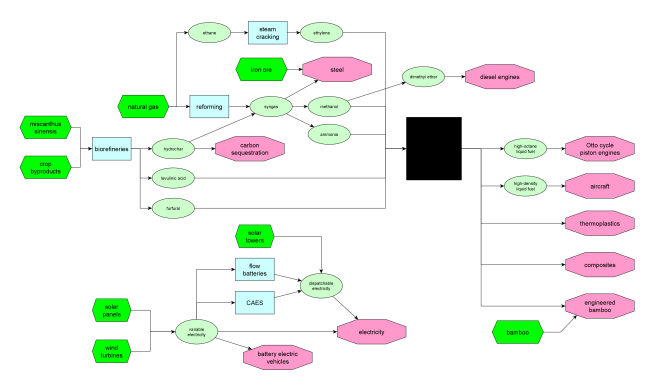

This is an overview of some proposed futures of the foundational parts of the economy, those related to energy and material production.

the current system

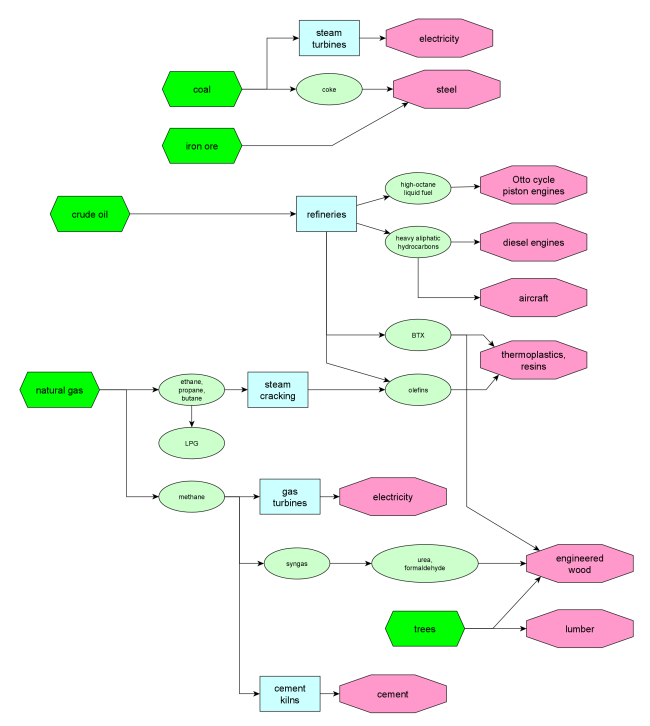

First, here's a flowchart for the

current US economy. (Yes, obviously this is very high-level and simplified.)

Why does this need to be changed? What are some

problems to try to solve?

Reduction of CO2 emissions is desired. The

easiest way to do that is to reduce coal usage by replacing coal power with

(natural gas + solar + wind) and that's already been happening in the USA

because it's cheaper than coal plants. Companies are also starting to

replace coal with natural gas for steel production. However, the USA now

only makes ~6% of the world's steel, and natural gas is more expensive in

most other places.

Sources of crude oil are limited, more so than

coal or natural gas. Oil is now significantly more expensive than other

sources of energy.

Piston-engine vehicles produce large amounts of

particulate pollution. Alternative fuels could reduce that pollution

greatly.

Trees take a while to grow, and lumber is usually more

expensive than in the USA. Engineered wood products mostly use

urea-formaldehyde resin, which can release (toxic) formaldehyde.

Concrete tends to crack over time, gets dirty when outside, and usually has

poor mechanical properties.

Current thermoplastics are either

expensive or have poor performance in some ways, such as strength, heat

resistance, UV resistance, hydrolysis resistance, etc. Current composites

are expensive. Many plastics contain toxic additives such as phthalates and

PBDEs. Biodegradable plastics are expensive and/or have poor performance.

Many plastics contain things that can't be easily incinerated.

So, let's look at some proposed alternatives.

cellulosic ethanol

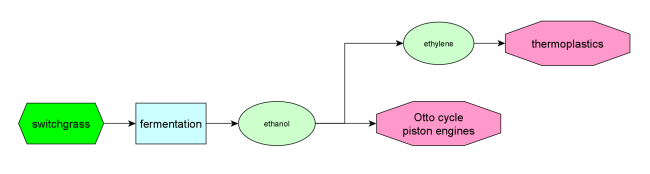

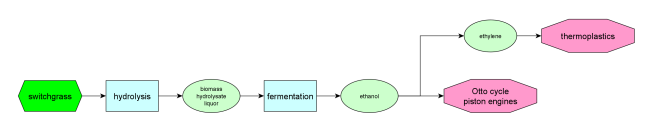

First,

cellulosic ethanol.

Normally ethanol is made by fermenting sugar or starch, but cellulose is

much cheaper. So, the US government has spent large amounts of money

researching this at places such as Idaho National Laboratory.

Some microbes can

digest cellulose, so why not just get some and engineer them to make

ethanol? Unfortunately, even small amounts of ethanol disrupt the

cellulose-degrading enzymes. This problem can't be solved and this approach

has now been abandoned.

Sulfuric acid can hydrolyze cellulose

into soluble sugars. Unfortunately, this also produces toxic compounds that

inhibit fermentation, and the required processing is expensive. I estimate

ethanol with this approach would be ~$8.5 per gallon of gasoline equivalent,

not including transportation or taxes, and I don't believe it can be cheaper

than fermenting sugar.

With gasoline prices above $5/gallon in the

USA in 2022, that might not sound so bad, but those high prices mostly come

from refiners making enormous profits because refining capacity is the

bottleneck.

Alternatively, cellulose-degrading enzymes could be produced and used to process cellulose for fermentation. However, microbes use a large fraction of the energy they get from cellulose to produce those enzymes, and cellulose degradation involves a complex combination of multiple microbes and enzymes that lose effectiveness if you try to isolate them. This ends up being more expensive than sulfuric acid, and I don't believe it can be cheaper than fermenting sugar.

burning biomass

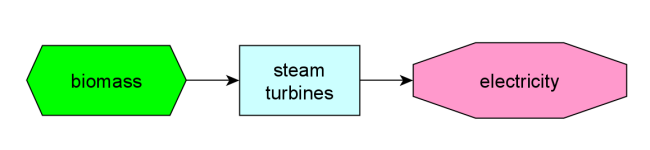

It's possible to burn biomass in

boilers instead of coal. There can be issues with ash melting and

accumulating on things, but this works well enough and has been used on a

large scale.

Biomass is perhaps 2x as expensive per joule as coal,

but the CO2 avoidance cost of using biomass instead of coal is quite low,

~$30/ton. There are 2 problems:

- in many

places, coal power isn't competitive, so the net cost is higher

- land

requirements

If you consider China, almost its

entire land area would be required to replace all its coal usage with

switchgrass.

I mention switchgrass because it's been the main focus

of US government research into biomass-based energy, but there are other

things that produce much more per hectare. The problem is that the plants

that give the most dry tons of biomass per hectare, such as "energy cane",

also require more fertilizer and water per ton. The supply of phosphate

fertilizer is also a long-term problem that exists.

clean coal

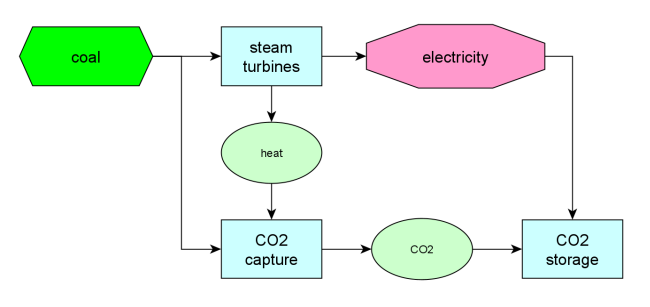

Then, there's "clean coal" - coal

power with CO2 capture and sequestration, perhaps underground at high

pressure. Coal produces flue gas with lots of CO2, and you can get heat

suitable for amine stripping of CO2 from that at the cost of some

efficiency, but capturing and storing CO2 is expensive and uses a large % of

the power from coal. Coal power is already too expensive without adding more

costs to it, and this would more than double the cost of it. The only reason

to do this is if you need large amounts of pure CO2, more than can be

captured from ammonia production and fermentation.

The US spent $7

billion on the Kemper

Project alone, which was cancelled without ever running.

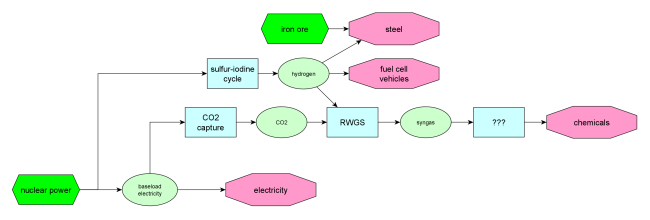

nuclear power

Another proposed future was a

nuclear one: electricity all coming from nuclear plants, and

high-temperature nuclear plants producing hydrogen fuel.

The main

problem is just that nuclear power plants are too expensive. The problem

wasn't really that nuclear got more expensive; it was that other stuff got

cheaper. Gas turbines were more like cars, and nuclear power plants were

more like houses, and construction of new houses got more expensive because

of...inflation, mostly. (If you look at the cost of construction vs

services over time,

the lines are pretty similar.)

And now, people have actually forgotten how to make them.

If you set aside geopolitical issues, coal is now generally more expensive than

natural gas. Nuclear power plants

are similar to coal plants

with a more expensive heat source, so they're more expensive than coal,

which is why China is still mostly going for coal over nuclear; their

nuclear plants only happened because China wanted a lot more nuclear weapons

and also thought some experimentation was worthwhile. Similarly, France made

lots of nuclear power plants because the government wanted lots of nuclear

weapons, not because they were actually cheap.

There's also the

problem of there not being enough nuclear fuel to run the whole world on

current nuclear reactors very long. The proposed solution was breeder

reactors, but those are less safe and even more expensive. Some people want

to get uranium from seawater, but they're delusional or can't do math:

processing seawater costs more than the electricity from uranium in it is

worth.

Nuclear hydrogen proposals were usually based on the

sulfur-iodine

cycle, but that involves a lot of high-temperature heat exchangers for

corrosive stuff, which is much too expensive - even if you assume free

nuclear heat. There are no hints of potential future solutions to that

problem unless you count people lying in university press releases.

Hinkley Point C is a nuclear

power plant under construction. An auction was conducted to see who'd be

willing to sell electricity at the lowest rate if they funded and built a

nuclear plant. The auction was won by groups associated with the French and

Chinese governments, and the result was a deal for very expensive

electricity. Despite that, it looks like those groups will be losing money

on the deal. That's about how you should expect nuclear projects to go.

As for TerraPower, it's worse than that - more expensive and also

unsafe.

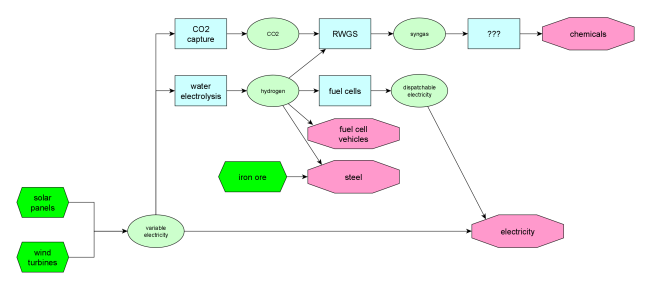

hydrogen

The "hydrogen

economy" has been another popular vision.

Low-purity hydrogen has

generally been a bit under $1000/ton in the USA recently, equivalent to a

bit under $0.025/kWh if electrolysis was 100% efficient. That's a bit less

than wholesale power from natural gas has been, which means that getting

hydrogen from natural gas is slightly easier than getting electricity from

it.

Of course, electrolysis isn't 100% efficient, and the

electrolysis systems typically cost more than the electricity that goes into

them, so H2 from electrolysis

would probably be $5/kg to $7/kg on a large scale.

Current electrolysis requires expensive rare metals and

gets 80% efficiency. Without the rare metals? If you use graphite, you'll

get maybe 40% efficiency and the anode will get oxidized too quickly. If you

do alkaline electrolysis with a porous nickel anode, you can get 65%

efficiency, but while that lasts longer than graphite, it still degrades

over time.

Fuel cells are the same thing in reverse, but efficiency

is more critical because if x is the loss, (1 / (1 + x)) > (1-x).

Underlying this proposal are assumptions that:

- solar power

costs will continue falling until it's $0.01/kWh or less

- water

electrolysis and fuel cells will be cheap if governments just insert enough

research money

Those are bad assumptions:

- As I

predicted, solar panel costs increased in 2021, and are increasing in 2022.

- There are always professors who say they'll provide X if you keep giving

them grant funding, but in this case they're delusional and/or lying.

Hydrogen fuel has established a constituency in universities and government departments that will defend it, and people who don't understand the technology involved see nothing but the backing it has, so the flow of money continues.

Hydrogen is a poor choice for vehicles, and at least on a large scale, fuel cells are too expensive and overall worse than gas turbines. That said, hydrogen has many uses. It can be:

- transported

by pipeline well enough

- stored in underground caverns cheaply enough

- used for steel production

- burned in gas turbines

- used with CO2

to make syngas

The main problem is "simply" that

hydrogen from electrolysis is much too expensive. Bill Gates wrote

this article

which basically says, "it would be nice if hydrogen from water electrolysis

was cheap".

OK, sure, but that's not insightful. It's not

useful. It would be nice if I had a billion dollars and a cure for

cancer, but I'm not going to write an article saying that. Water

electrolysis is too expensive, that's not changing, Bill Gates isn't going

to change it, and also Breakthrough Energy Ventures makes

bad investments so I

wouldn't follow their lead.

One proposed way to use hydrogen

is to ferment H2 and CO2 to get chemical products. Unfortunately, due to

thermodynamic limitations, basically the only products you can get from that

are methane and dilute acetic acid.

So, suppose you do RWGS and turn

that into syngas. With CO, there are more options, but there's another

problem with syngas fermentation: H2 and CO have very low solubility in

water, so even if you try to make small bubbles, the transfer between gas

and solution is so slow that the process ends up being too expensive. Syngas

fermentation isn't practical.

batteries

Perhaps you've

seen articles saying that Li-ion batteries are down to $132/kWh according to

a BloombergNEF survey? That was heavily weighted towards subsidized Chinese

prices for batteries used in Chinese vehicles. In 2020, the average price

per kWh excluding China was over 2x their global average. But of course,

journalists are lazy, so they just report the average.

The basis of

this plan is a view that Li-ion battery prices have fallen, so they'll

continue to fall exponentially down to maybe $30/kWh. That's silly if you

put any thought into it, and in 2022, Li-ion battery prices have increased

significantly, so I guess those naive projections weren't quite right.

In 2019, Tesla charged $265/kWh for large (utility-scale) lithium-ion

batteries. That was almost at-cost, and doesn't include construction,

transformers, or interconnects, which add >$100/kWh. I could see real costs

falling to $200/kWh but not to $100/kWh.

LiFePO4 batteries are often

described as having a cycle life of 5000 cycles. At 5% interest, that would

be maybe $0.09/kWh stored, on top of the cost of electricity input. That's

too expensive to compete with US natural gas, but it's also less than the

surcharge Californians pay from PG&E corruption.

How about

degradation over time? LiFePO4 generally lasts for 5 to 20 years, depending

on the temperature and charge state. (High temperature is worse.) That's

similar to the cycle life.

That's not so bad, and Li-ion costs could

come down somewhat. $200/kWh for LiFePO4 is plausible. Cycle life is OK,

degradation over time is OK, so everything is fine, right? WRONG! A "SEI"

layer forms in Li-ion batteries, which thickens over time, increasing

resistance and reducing capacity but protecting the battery from

degradation. Cycling the battery breaks up the SEI layers somewhat, which

affects

degradation over time.

But Li-ion battery degradation isn't

understood very well by most people, and investors and executives and

government officials just look at the cycle life if they even think about

degradation at all. Anyway, 5000 cycles is too optimistic, and I expect

something more like 2000 cycles for LiFePO4 in a grid energy storage

application, and an incremental (not including input) cost per kWh of ~$0.20

- which is too expensive.

You can also think about the cost per kWh

and per mile of a battery in an electric car this way, and it ends up being

considerable, similar to the cost of gasoline.

LiFePO4 has a good

cycle life, but it's also heavier than other Li-ion types, so other

chemistries are generally preferred for cars. The cost of battery wear from

charging and discharging car batteries would, in general, be worth more than

that much grid energy storage. Using the batteries of electric cars to store

excess energy from solar panels and balance demand has been a common

proposal, but it's not economically a good idea.

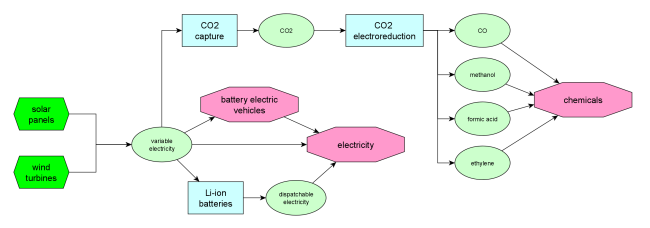

It's not

strictly tied to batteries, but I put "direct CO2 electroreduction" here.

This has been a big research focus in US and European universities, because

a lot of funding was devoted to it, but it's not a good idea. Water

electrolysis isn't good either, but this is much worse.

The easiest

thing to make by direct electrolysis of CO2 is, by far, CO. Making CO from

CO2 is essentially running a solid oxide fuel cell in reverse. Those are

expensive, too expensive to use for making electricity from natural gas.

Making other stuff is much harder, and generally is inefficient and requires

too much expensive rare metal. Costs would need to come down by a factor of

perhaps 20 - from optimistic extrapolations to large scales, not from

laboratory costs - for this to be viable, and they definitely won't.

my proposal

Here's what I suggest instead. This might seem arcane or

arbitrary, but there's a certain inevitability to the logic of it.

Handling solid material is much more expensive than handling liquids and

gases. Lignocellulosic biomass is so cheap and so low-value that very few

options for processing it are cheap enough:

A) truck it short distances,

<200 km

B) store it in hay bales for a while

C) feed it to animals

D) grow mushrooms on it

E) burn it in a boiler

F) grind it up

G) put it in hot water

with a small amount of additives for a short time

(A)-(D) are common

and work well. (E) is done sometimes and was historically important, but

coal is much cheaper per joule. That leaves (F) and (G), and (levulinic acid +

furfural + hydrochar) is simply what you can get if you choose those.

Even then, processing biomass is generally more expensive than buying

it. A typical analysis is:

- biomass =

$75 / dry ton

- processing cost = $150 / biomass dry ton

- cellulose +

pentose fraction = 2/3

- furfural + levulinic acid yield from cellulose +

pentose = 30%

- cost = (75 + 150) / (0.3 * 2/3) = $1150/ton

Obviously, if you want to make furfural and levulinic acid for less than that, you need to reduce processing costs and/or increase yields. It's also important to get some value out of the hydrochar, even if that's just burying it for carbon credits. I believe it's possible to get that average price below $700/ton.

In the flowchart I specify Miscanthus sinensis as the source of on-purpose biomass, but there's wide variation across the subspecies of it, and only some of them are suitable.

As for methanol, it has 1.4x the

energy per mass of glucose, which makes it cheaper per output if you can

engineer microbes to use it. Cane sugar is ~$300/ton. If you gasify raw

biomass and make methanol, the processing costs more than the biomass, but

it's still slightly cheaper than using sugar - and methanol from natural gas

is much cheaper. If making levulinic acid and furfural is economically

viable, then you get free hydrochar, which is a better fuel than raw biomass

- similar to coal but with less mercury and sulfur. Alternatively, you can

bury hydrochar for carbon sequestration. Burying something is more expensive

than not digging up coal, but if coal

isn't worth using, then maybe carbon sequestration is worth more than its

value as fuel.

I've thought about the details of biorefineries some,

but most of my thinking on this has gone into the details of that black box.

I'm now confident that production of (levulinic acid + furfural) can be done

cheaply enough, and that there are good routes from methanol, ammonia,

levulinic acid, and furfural to basically every chemical product needed on a

large scale. The details are complex and figuring this out was challenging.

Certain flow batteries are the most promising future type of grid

energy storage, but the membranes for them are currently too expensive.

Currently, certain compressed air energy storage (CAES) systems are the

best grid energy storage approach. Specifically, certain hydraulically

compensated constant-pressure adiabatic CAES designs, similar to

what

Hydrostor is doing with some minor variations.

Solar-thermal

power towers with thermal energy storage are only viable in certain

locations with lots of sun and few clouds, and they're also currently much too

expensive, but it's possible to make them cheaply enough to sometimes be

better than storing power from PV solar. Previously, thermal energy storage

on a large scale using power towers and nitrate salts was planned, but in

practice, heat exchanger corrosion from that turned out to be too expensive

to deal with for it to be practical. See also the

Ivanpah

project that turned out to make much less power than expected because

clouds were somehow underestimated. Again, current designs are not good;

major changes are needed for this to be viable even in good locations for

it.